Home > Ultrasonic components

Ultrasonic components

Accessories

Sonic Italia develops internally a wide range of accessories which are used both with its own production systems and as components for frequency measurements

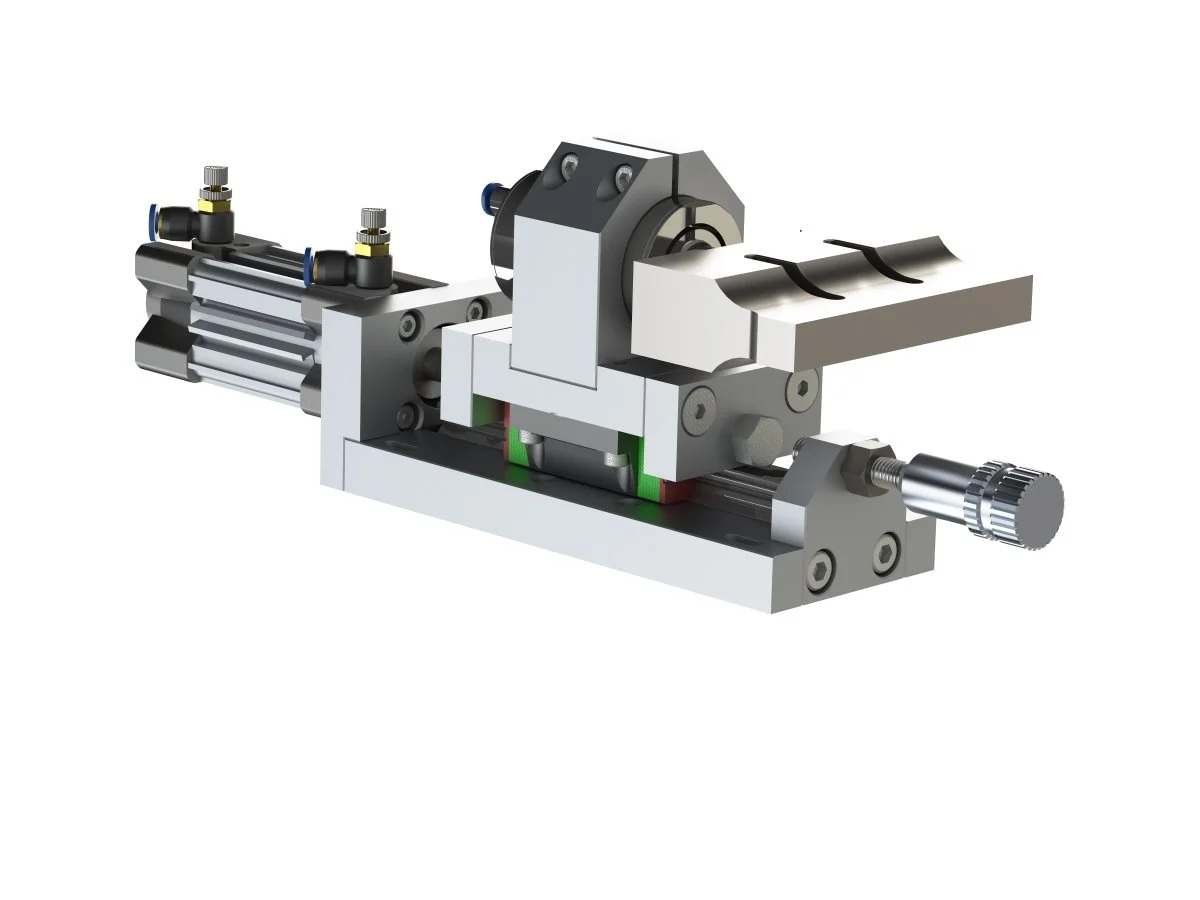

PNEUMATIC ACTUATORS

Pneumatic actuators Sonic Italia manufacturers very high-precision pneumatic actuators for Companies needing an integration of ultrasonic welding.

CUSTOMIZED AUTOMATIONS

Sonic Italia develops customized semi-automatic systems to meet customer’s production targets.

ULTRASONIC GENERATORS

Sonic Italia manufactures a wide range of ultrasonic generators from 1200 to 4000W of power designed for any presented need on the market.

CONTINUOUS WELDING SYSTEMS

Sonic Italia developed an optimal continuous welding module for packaging and pleated filters.

ULTRASONIC CUTTING SYSTEMS

Sonic Italia is specialized in the manufacturing of ultrasonic cutting systems of different frequencies and powers, easy to install on different types of machines.

ULTRASONIC WELDING MACHINE

Sonic Italia produces ultrasonic presses for welding plastic components with 30, 35, 40 Khz frequencies up to 1200W, and 20 Khz frequencies up to 4000W.

ULTRASONIC HAIR EXTENSIONS WELDING KIT

Design made in Italy, designed to achieve professional performance.

ULTRASONIC PORTABLE WELDING KITS

Sonic Italia produces portable systems of different frequencies and powers, with ergonomic and light handgrips designed to be used by any operator.

ULTRASONIC PORTABLE CUTTING KITS

Sonic Italia manufactures a wide range of portable ultrasonic cutting systems, designed to meet the requirements of the markets in which this type of machine is used.

ULTRASONIC SONOTRODES AND BOOSTERS

Sonic Italia's technical department has the right solution for each customer's needs.

Ultrasonic Converters

Sonic Italia developed transducers covering the entire range from 20, 30, 35 and 40 kHz made of titanium and aluminum alloys.

Ultrasonic components: the right solutions for every need

All our products are designed and developed in-house after careful research and experimentation. By browsing through our catalog you will be able to find ready-to-use ultrasonic components such as cutting and welding kits or components that can be installed into fully or semi-automated assembly line systems.

Following on the client’s requests and needs, our technical department will study and devise the options that best suit their specific guidelines. Whether it is for the quality of the desired end product or the ease of implementation, rest assured that both our standard and custom-made peripherals can fulfill all your demands.

The first stage in the creation of new ultrasonic components lies in studying the so called energy directors. Their shape, the use of properly weldable materials and the position of the product may determine the success or failure of the assemblage process.

Important facts about ultrasonic components

In order to attain satisfactory results, it is advisable to take in mind the following factors:

- It is necessary to weld in a reduced contact surface to achieve a great concentration of energies and a quick fusion;

- Proper positioning of one of the parts so that it can vibrate freely in relation to the rest, creating the base of the meld;

- A dedicated space for putting molten material to prevent external burrs;

- If possible, a welding frame that is parallel and/or perpendicular to the ultrasonic vibration vector;

- Avoid that pieces get deformed due to molding or retrieval;

- The width of the object touching the sonotrode must be wide enough for the plastics to hollow out when they get the ultrasonics treatment;

Sonic Italia offers free laboratory tests of its gadgets on a specific artifact and guarantee the best results for any given demand.