Home > Industry specific Ultrasonic solutions > Ultrasonic Cutting for Synthetic Fabrics

Ultrasonic Cutting for Synthetic Fabrics

Ultrasonic technology

Ultrasonic technology in the Textile/Non-woven industry is commonly applied.

On non-woven fabrics, synthetic and mixed fabrics, ensuring speed, clean cutting and welding precision.

The repetition of the process, the low energy consumption and the ability to operate 24/7 online has made many companies choose our technology for their production lines.

Applications

PUNCHING

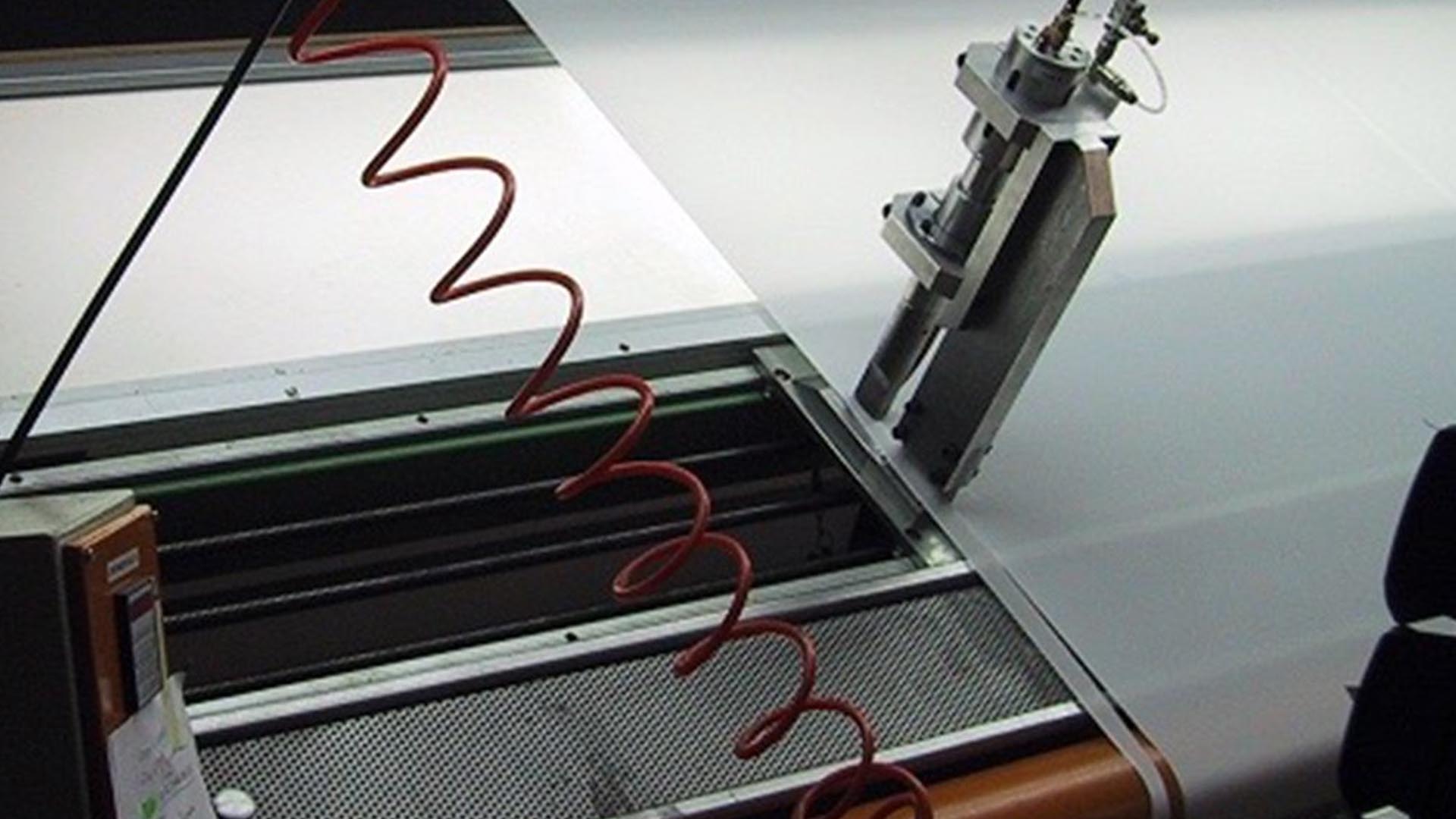

CONTINUOUS WELDING

ULTRASONIC WELDING AND CUTTING PROCESS (PORTABLE)

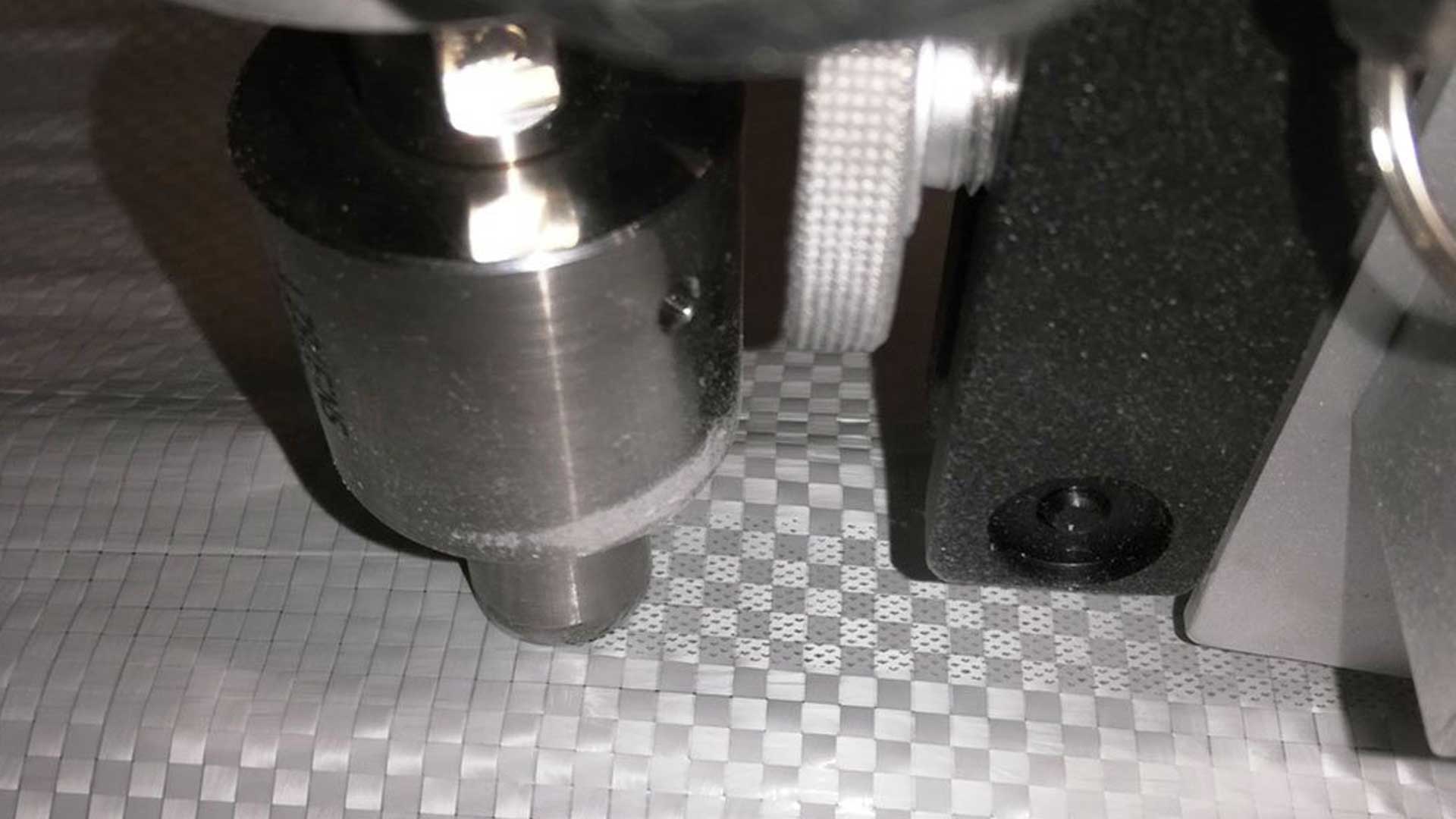

ULTRASONIC CUTTING AND WELDING PROCESS

STEP-BY-STEP ULTRASONIC WELDING

GUILLOTINE ULTRASONIC CUTTING

ULTRASONIC BONDING

ULTRASONIC CUTTING

ULTRASONIC WELDING AND CUTTING ON CIRCULAR LOOMS (RAFFIA BIG BAGS)

Required thermoplastic materials

The synthetic fabrics that work best with ultrasonic cutting machinery are those that contain thermoplastics with similar melting temperatures and compatible molecular structures.

In order for the ultrasonic cutting to work properly, synthetic fabrics should all share the following characteristics:

- Wide melting range

- High friction coefficient

- Uniform thickness

- At least 25 % of thermoplastic contents

- Enough stiffness and thickness to take the energy on the material’s interface (0,32258 mm / 0,0127 mm minimum)

Polyester is considered to be the most suitable synthetic material to be subjected to ultrasonic applications.

Moreover, ultrasounds can generate strong and long-lasting seams in synthetic elements like Nylon 6 and Nylon 6/6 as well.

Most polyolefins (polypropylene and polyethylene), on the other hand, show excellent welding characteristics, plus they are very lightweight. This makes them to lend themselves to various industrial uses.